Design lasted months with multiple checkpoint packages sent to the client for review. Panels were fabricated at a top-tier panel shop, and the finished panels checked before shipping to the field.

During a field visit, the Construction Manager said that the electrical contractor had some questions about where to land field wiring and implied that the drawings were wrong.

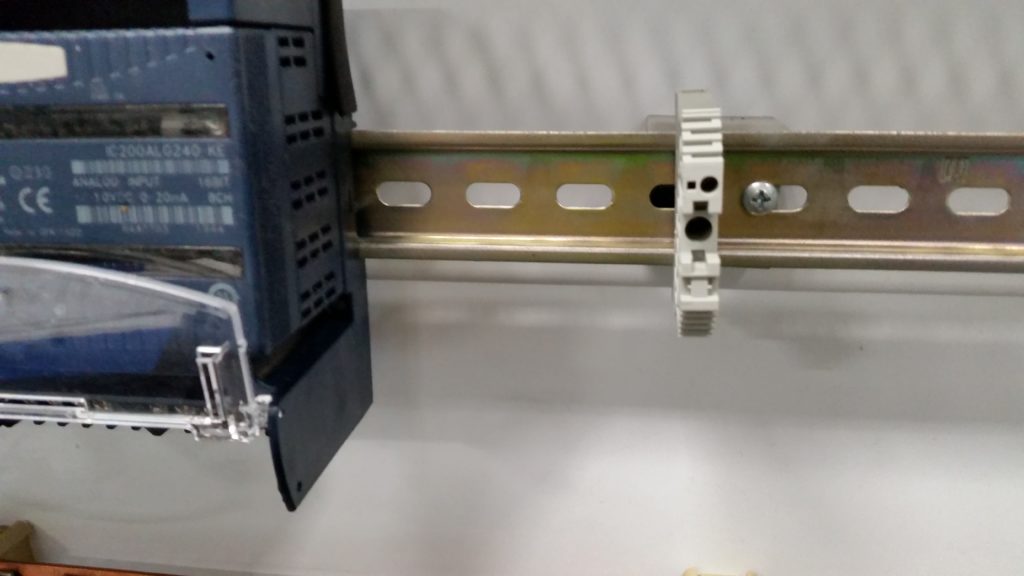

Discovered that shortly after the panels were set in place, but before the electrical contractor had a chance to begin wiring, the owner’s staff began applying unaforementioned improvements, by cutting panel wiring and moving modules.

Moving modules changed their I/O point addresses, putting the physical arrangement out-of-sync with the drawings. The owner’s staff didn’t advise anyone of what was going on, and left their changes “in progress”.

When the electrical contractor began installing field wiring to the panel, the module layouts didn’t match the drawings, and the drawing I/O addresses no longer were valid, with many pointing to the wrong module type.

The end result: confusion, delayed completion, and worthless documentation.